May can use this when we build a front-end for our receiver. Storing it here so I will not lose it.

Wednesday, April 20, 2016

Tuesday, April 19, 2016

Storing a couple of ideas for future projects.

This simple two penny coupler could come in handy so I'm filing it while I have it handy. We had a discussion about making and using gimicks. Twist two pieces of insulated wire together and use it as a capacitor. It works but to adjust it you have to trim. twist , or untwist it. This one uses binding post but you could thread the wire (12 gauge is the size of #4 screw) and make a screw adjustment.

Here we have another way to core a transformer. I've used this one and the toroid. They both work. I don't know if one is better. Maybe some time I'll build two cores and wind them the same then use toroid on one and this method on the other then have something to compare.

EDIT: This method is easier to provide an air gap. The toroid is easy to install and works well in circuits that don't require an air gap.

Here we have another way to core a transformer. I've used this one and the toroid. They both work. I don't know if one is better. Maybe some time I'll build two cores and wind them the same then use toroid on one and this method on the other then have something to compare.

EDIT: This method is easier to provide an air gap. The toroid is easy to install and works well in circuits that don't require an air gap.

Dual gate MOSFET amp prototype.(BF2040W)

The scope is reading the output of the last stage. pretty good signal.

I used two 10 KOhm and a 22 KOhm to make the voltage divider so it isn't "dead on" but close enough. The 1 Volt bus is 1.19 Volts.

The 4 Volt bus is 3.83 Volts. If the designer wanted he could use a pot instead of fixed resistors but I think it's close enough. Time to find out. I put the coil I made in the unusual IF post and a ear phone on it and lots of rush hissing in my ear. I used a screw driver as a core to adjust and I hear a weather report. I waited for the station ID and it was WWL New Orleans. I ask google and he said I am 135 miles from them. Not to bad my antenna is a test lead clipped to an AC duct.

Close up of the amp. I have the parts spread out so it's easy to work with. I'm using inductors in the drain circuit and capacitor coupling. The five blue things in the middle are 8.2 nfd caps. I'm thinking I will replace them with 10.7 Mhz resonator and have an IF strip. The circuit works but I probably should put some decoupling caps in it.I posted this picture so you can see my use of copper foil (found in the stained glass supplies) and head pins (found in the jewelry making supplies). The foil provides a bus to solder to and the pins can be used for wire wrap and clipping test leads.

Examing the datasheet to see what the MOSFET biasing should be.

Dual gate MOSFET cascode?

As can be seen the chip has source 1, channel 1, drain 1 and source 2 as one element, channel 2, drain 2.

There are two transistors in series. This is called a casdode circuit. Let's take a closer look at a cascode circuit.

As can be seen here this is a common gate amp 'stacked' on a common source amp. Why would we want to build a circuit like that? I hope to answer that question next post.

Friday, April 15, 2016

Wednesday, April 13, 2016

How to make an IF transformer for that odd frequency.

Someone ask where to get IF cans another asked what the IF in an antique radio was. They are after parts to build that radio of their dreams. Sometimes NOS is available or a parts only relic which has already seen its last days of service other times it is best to just build your own. One of them was after a 1600Khz IF transformer so that will be the goal. If I were building one to use I would put a trimmer cap on it but this is a demo only so I'll use a fixed cap and get 'close'.

The first steps to inventory the parts bin and find suitable material.

Look at the chart I can use a core from 1/2" to 12". I was involved in a plumbing project not very long ago and saved some PEX. The 1/2" pipe is 5/8" OD.

First piece of scrap I picked up is about 3-1/2" long, that could do nicely. Let's try a design around it. I'm using #24 wire which is 47TPI and I'm going with a 3" length. Drawing a line between 47TPI on the second column and 3" on the third column establishes the index. I'm using a 5/8" core so I draw a line from 5/8" on the first column through the index point. This gives an inductance of 65 micro henry. All that is left is to determine the wavelength and draw a line from the inductance to through the wavelength to determine the capacitance. If everthing stays on the chart the design is good. Now to build the coil.

The PEX uses a locking ring connector so I use one of the rings to mark the end mark. Measure the other end and mark it the same. This is not necessary but it helps keep everything in line.

I threaded a #14 wire on both ends and drilled and tapped the PEX to accept it. Screw the wire in and trim it to length.

I had to decide if the coils will terminate on one end or both ends. I went with both ends so i put two terminals on each end.

The meter shows 70 micro henry. I wound one coil 3" and the other 1". giving a 3 to 1 turns ratio.

I put a cap across it and feed a signal until the output peaked. Just the first cap I pulled out of the bin. The input was 25 mv with 1.33v out. It could use a slug or a trimmer capacitor to tune it but for now it is a proof of concept.

EDIT:

I started designing for 1600KHz. The frequency meter is displaying 1882KHz. With more capacitance I could achieve the 1600KHz goal.

Look at the chart I can use a core from 1/2" to 12". I was involved in a plumbing project not very long ago and saved some PEX. The 1/2" pipe is 5/8" OD.

First piece of scrap I picked up is about 3-1/2" long, that could do nicely. Let's try a design around it. I'm using #24 wire which is 47TPI and I'm going with a 3" length. Drawing a line between 47TPI on the second column and 3" on the third column establishes the index. I'm using a 5/8" core so I draw a line from 5/8" on the first column through the index point. This gives an inductance of 65 micro henry. All that is left is to determine the wavelength and draw a line from the inductance to through the wavelength to determine the capacitance. If everthing stays on the chart the design is good. Now to build the coil.

The PEX uses a locking ring connector so I use one of the rings to mark the end mark. Measure the other end and mark it the same. This is not necessary but it helps keep everything in line.

I threaded a #14 wire on both ends and drilled and tapped the PEX to accept it. Screw the wire in and trim it to length.

I had to decide if the coils will terminate on one end or both ends. I went with both ends so i put two terminals on each end.

The meter shows 70 micro henry. I wound one coil 3" and the other 1". giving a 3 to 1 turns ratio.

I put a cap across it and feed a signal until the output peaked. Just the first cap I pulled out of the bin. The input was 25 mv with 1.33v out. It could use a slug or a trimmer capacitor to tune it but for now it is a proof of concept.

EDIT:

I started designing for 1600KHz. The frequency meter is displaying 1882KHz. With more capacitance I could achieve the 1600KHz goal.

Sunday, April 10, 2016

Dual gate MOSFET - surface mount to leaded

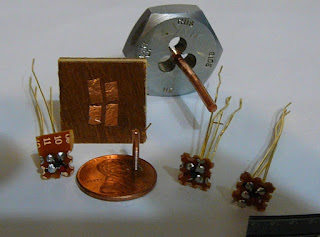

You can go to any hobby supply with a jewelry section and get a pack of head pins. Gold or silver plated will work.

Place them in some perf board and tin them. You don't have to tin them but I think it works best.

place the chip on the board and solder them. You will have leaded transistors.

Here I have separated them. I put a red dot on the source so I can ID it. You could trim the board and put a drop of epoxy on them to make it more like a transistor.

Just for size comparison I have a #4-40 die with a piece of #12 wire in it and a penny. I did put some on the 1" square board also.

Hats off to Andy again. When I presented the thread on soda straw variable inductor he suggested using #4-40 screw to get fine tuning. The 'rod above is #12 solid copper wire. It's a perfect fit in the #4-40 die.

Place them in some perf board and tin them. You don't have to tin them but I think it works best.

Here I have separated them. I put a red dot on the source so I can ID it. You could trim the board and put a drop of epoxy on them to make it more like a transistor.

Just for size comparison I have a #4-40 die with a piece of #12 wire in it and a penny. I did put some on the 1" square board also.

Hats off to Andy again. When I presented the thread on soda straw variable inductor he suggested using #4-40 screw to get fine tuning. The 'rod above is #12 solid copper wire. It's a perfect fit in the #4-40 die.

Tuesday, April 5, 2016

Some more circuits to build with

Some more circuits. The list is RF amp, IF amp, mixer, product detector, and regen detector. With so many building blocks it could be a regen or superhet or direct conversion.

Dual gate mosfets

JFET radio

Subscribe to:

Comments (Atom)