This is what my component tester says about the transistor in the black box. Now that's some food for thought. Gernsback's test says it is Point Contact transistor. Component tester says it is a Field Effect Transistor.

Maybe I should use Gernsback's test on a FET and see how it test???

Wednesday, February 28, 2018

Saturday, February 24, 2018

Testing an unknown transistor

I mounted a transistor in the black box. The object is to test it and see what we can tell from a simple test.I will need an ohmmeter,voltmeter, resistor from 500 to 1500 ohms and a battery ( or power supply).

The ohmmeter MUST be 1ma or less. My meter is 2KOhm per volt or 500ua so I just use the highest range. The lower range will shunt the meter and use more current. I will also need to know the meter polarity. When using a multi meter for voltage the red lead is positive but most ohmmeters will have the red negative. (it's the difference between sourcing and sinking. The volt meter reads an external source while the ohmmeter is powered by a built in battery.)

I hooked the red to black and black to red as you can see the polity is correct so my red lead is negative. I will show the test and a table of readings.

This is my black box component. The tilted lead is #1.

If you examine the table you will see when term 2 is negative I get the same readings to terminals 1 and 3 so the device is PNP and term 2 is the base. To make the test I connect the meter between term 1 and term 2 with the negative on term 2. I will put a resistor between term 2 and the positive power supply with the negative on term 3. The simpler statement is forward bias 1 and 2 with the ohmmeter and reverse bias term 2 and 3 with a power source feeding through a resistor. In my test I am using a 1.2K resistor and 3 volts power supply. So now drum roll and display the test results......................

As you can see the meter goes below ZERO Ohms. Mr Gernsback says use a 500 ohm resistor and a 6 volt battery. I used the 1.2K because i have a drawer full within reach. The reading went negative befor I reached 3.0 volts too. This transistor could be exceptionally strong and the next may need a little more potential but I have tested a half dozen with this setup and had the same results.

Now to analyze the results. What does it tell me? This test tells me something about the way the transistor was manufactured. The meter going below zero indicates an alpha greater than 1. Point contact transistors have an alpha greater than 1. The reading will drop with a micro alloy transistor but not past zero. Modern silicon transistors may so a flicker as the power is applied and removed but will not drop very much. So what's in the box is a point contact PNP transistor.

The test jig schematic.

You can do a quick test with some test leads or breadboard. If you plan to test several it may be worth making a little test board. I should point out the Ohmmeter is forward biasing the Emitter - base junction and the power supply is reverse biasing the base - collector junction.

LOOK AT THE NEXT POST TO SEE WHAT MY COMPUTER BASED TESTER SAYS IS IN THE BOX??????

The ohmmeter MUST be 1ma or less. My meter is 2KOhm per volt or 500ua so I just use the highest range. The lower range will shunt the meter and use more current. I will also need to know the meter polarity. When using a multi meter for voltage the red lead is positive but most ohmmeters will have the red negative. (it's the difference between sourcing and sinking. The volt meter reads an external source while the ohmmeter is powered by a built in battery.)

I hooked the red to black and black to red as you can see the polity is correct so my red lead is negative. I will show the test and a table of readings.

This is my black box component. The tilted lead is #1.

If you examine the table you will see when term 2 is negative I get the same readings to terminals 1 and 3 so the device is PNP and term 2 is the base. To make the test I connect the meter between term 1 and term 2 with the negative on term 2. I will put a resistor between term 2 and the positive power supply with the negative on term 3. The simpler statement is forward bias 1 and 2 with the ohmmeter and reverse bias term 2 and 3 with a power source feeding through a resistor. In my test I am using a 1.2K resistor and 3 volts power supply. So now drum roll and display the test results......................

As you can see the meter goes below ZERO Ohms. Mr Gernsback says use a 500 ohm resistor and a 6 volt battery. I used the 1.2K because i have a drawer full within reach. The reading went negative befor I reached 3.0 volts too. This transistor could be exceptionally strong and the next may need a little more potential but I have tested a half dozen with this setup and had the same results.

Now to analyze the results. What does it tell me? This test tells me something about the way the transistor was manufactured. The meter going below zero indicates an alpha greater than 1. Point contact transistors have an alpha greater than 1. The reading will drop with a micro alloy transistor but not past zero. Modern silicon transistors may so a flicker as the power is applied and removed but will not drop very much. So what's in the box is a point contact PNP transistor.

The test jig schematic.

You can do a quick test with some test leads or breadboard. If you plan to test several it may be worth making a little test board. I should point out the Ohmmeter is forward biasing the Emitter - base junction and the power supply is reverse biasing the base - collector junction.

LOOK AT THE NEXT POST TO SEE WHAT MY COMPUTER BASED TESTER SAYS IS IN THE BOX??????

Thursday, February 22, 2018

Source of phos bronze for points.

If you use a breadboard you may have some of these. With a little effort you can iron one out flat and have a sort for several points. You can lay 3 on a dime. The section are quite small so all they need is pointing and mounting on a wire. You could use a #20 or larger and simple solder the point to it. So here is the female breadboard jumper connector before and after flattening.

This is as bought.

This is flattened.

The carrier strap on the new connector could be split and make two strips.

You could cut the "L" from the top.

Cut the strip in half and separate the sections of the pitch fork.

Split the stub down the middle and use the two spurs.

So one of these gives all of that. Time to get the scissors out and do some trimming.

Edit:

I found some #26 phosphor bronze wire on Amazon. It is $8 for a 1/4 pound roll. That would be a life time supply for a hobbyist. It is a little large but can be hammered flat or even mashed with a pair of pliers.

They have phosphor bronze shim stock that is thin enough but would have to be cut in strips.

Just a couple of more options.

Edit 2:

I found a source for .008" shim stock in phosphor bronze material. A 6" X 12" sheet would be a lifetime supply for a hobby builder.

This is as bought.

This is flattened.

The carrier strap on the new connector could be split and make two strips.

You could cut the "L" from the top.

Cut the strip in half and separate the sections of the pitch fork.

Split the stub down the middle and use the two spurs.

So one of these gives all of that. Time to get the scissors out and do some trimming.

I found some #26 phosphor bronze wire on Amazon. It is $8 for a 1/4 pound roll. That would be a life time supply for a hobbyist. It is a little large but can be hammered flat or even mashed with a pair of pliers.

They have phosphor bronze shim stock that is thin enough but would have to be cut in strips.

Just a couple of more options.

Edit 2:

I found a source for .008" shim stock in phosphor bronze material. A 6" X 12" sheet would be a lifetime supply for a hobby builder.

Wednesday, February 21, 2018

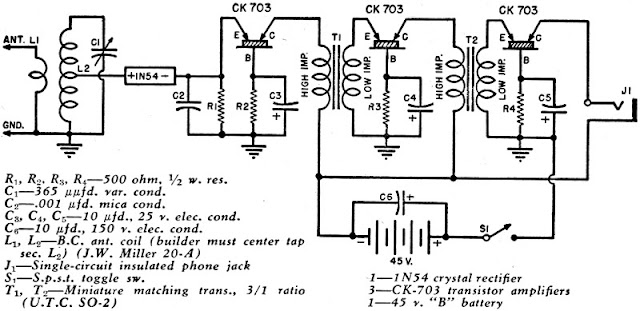

Point Contact and Junction first generation circuits to play with.

The original release of the transistor was not an over night thing. Some dealers would only sell to businesses and some would only sell in quantity. As a teen I worked in a Radio & TV repair shop and could buy through the store account. They were not cheap but i did get my hands on a few to tinker with. I don't think the point contact was ever readily available. The early junction devices were easier to get. Anyway the first published transistor radio I am aware of was in 1950.

The interesting thing here was they state in the article the transistors were difficult if not impossible to buy. I guess you could say for information only? The next generation transistor radio would be this one.

I made the first one using sockets so I could try different transistors. I used some transformers I have in the shop. It worked! I have several transistors in the bins that worked in the circuit. In order to do it right I will have to wind transformers and make the point contacts. More on that later.

You can see the second one is more complicated with all those pots adjusting the bias. What else is different? If you made this circuit with modern transistors it would not work because the Emitter - Base junction needs forward bias. Let's take a look inside the transistor.

Here we have the first and second generation transistor. (Inside design.) The point contact has the point placed in contact and then 'formed' with a pulsing current. This creates an alloy at the point of contact. The junction has a ball of solder on the point which is then soldered to the wafer. In essence they are the same but the micro alloy is more easily controlled in the junction transistor. It is not apparent so a little explanation. If I were mass producing the junction units I would cut slabs from the Germanium bar to fit the job and then wash it to remove impurities and form a dip for the solder to flow into (the emitter and base on opposite sides of the wafer establish the spacing.). Then they are ready to be soldered. It would be an assembly line operation step by step .....

The point contact on the other hand would have the slab soldered in place and then the cat whiskers positioned and attached. The two points must contact an active spot on the slab and closely spaced. You might set one wire and the not be able to set the second. This requires moving the first. When they are finally positioned they must be formed. The forming process will not be repeatable because of impurities and surface oxide ......

So you could have a line making cans and attaching lead wires. Another soldering the wires to the slabs and a third placing the wafers inside the cans and attaching them in place. This would allow more production in making the junction transistor. Faster and cheaper takes the market.

Anyway plans are always subject to change but the present plan is to build the two circuits and see how they function. transformers to wind and transistors to collect or make.

Let the fun begin.

The interesting thing here was they state in the article the transistors were difficult if not impossible to buy. I guess you could say for information only? The next generation transistor radio would be this one.

I made the first one using sockets so I could try different transistors. I used some transformers I have in the shop. It worked! I have several transistors in the bins that worked in the circuit. In order to do it right I will have to wind transformers and make the point contacts. More on that later.

You can see the second one is more complicated with all those pots adjusting the bias. What else is different? If you made this circuit with modern transistors it would not work because the Emitter - Base junction needs forward bias. Let's take a look inside the transistor.

Here we have the first and second generation transistor. (Inside design.) The point contact has the point placed in contact and then 'formed' with a pulsing current. This creates an alloy at the point of contact. The junction has a ball of solder on the point which is then soldered to the wafer. In essence they are the same but the micro alloy is more easily controlled in the junction transistor. It is not apparent so a little explanation. If I were mass producing the junction units I would cut slabs from the Germanium bar to fit the job and then wash it to remove impurities and form a dip for the solder to flow into (the emitter and base on opposite sides of the wafer establish the spacing.). Then they are ready to be soldered. It would be an assembly line operation step by step .....

The point contact on the other hand would have the slab soldered in place and then the cat whiskers positioned and attached. The two points must contact an active spot on the slab and closely spaced. You might set one wire and the not be able to set the second. This requires moving the first. When they are finally positioned they must be formed. The forming process will not be repeatable because of impurities and surface oxide ......

So you could have a line making cans and attaching lead wires. Another soldering the wires to the slabs and a third placing the wafers inside the cans and attaching them in place. This would allow more production in making the junction transistor. Faster and cheaper takes the market.

Anyway plans are always subject to change but the present plan is to build the two circuits and see how they function. transformers to wind and transistors to collect or make.

Let the fun begin.

Just makes me go ,huh?

A younger guy on a board was talking about the early transistors and it seems his opinion is we (the older guys) were stupid because we weren't born knowing how they functioned and how to fab the circuits he uses today?

It is a little amusing sometimes the way people who grew up with electronics see thing differently from the ones who have never been without.

Then the self proclaimed expert begin to explain how they work? In his expert opinion all the theory being taught for the last 70 years is wrong.

What really made me go, HUH? Was when he declared Sze's physics was irrelevant and flawed.

Two first year students used Sze's book as as guide and made working transistors yet Sze is flawed?

The major manufactures us Sze as a standard and build chips with a billion transistors on them and they work yet Sze is flawed.

Anyway rant is over. I think the three who came up with this were genius's.

Seventy years later with their example to go by some still have trouble replicating it. Yes that was the first transistor ever presented to the public. I guess I was not along in thinking them genius's, they were given the Nobel prize for it. Here is some more genius in action.

92 point contact transistors and 550 diodes equals computer. What a project that was!

That guy buys a TA7642 and puts a few components on a board with it and thinks, "Oh what a brilliant fellow am I!". He even calls it a one active device radio. I guess he doesn't know the TA7642 has 10 transistors in it?

Anyway the point contact was the first transistor to achieve military standards and it was used in early computers. The cost and lack of supply channels was probably what killed them. The early components were soldered together so excess heat in installing them could kill one. This applied equally to the junction transistors. That was why they came with such long leads. The maker warned to place a heat sink on the lead between the solder joint and the tranny.

It is a little amusing sometimes the way people who grew up with electronics see thing differently from the ones who have never been without.

Then the self proclaimed expert begin to explain how they work? In his expert opinion all the theory being taught for the last 70 years is wrong.

What really made me go, HUH? Was when he declared Sze's physics was irrelevant and flawed.

Two first year students used Sze's book as as guide and made working transistors yet Sze is flawed?

The major manufactures us Sze as a standard and build chips with a billion transistors on them and they work yet Sze is flawed.

Anyway rant is over. I think the three who came up with this were genius's.

Seventy years later with their example to go by some still have trouble replicating it. Yes that was the first transistor ever presented to the public. I guess I was not along in thinking them genius's, they were given the Nobel prize for it. Here is some more genius in action.

92 point contact transistors and 550 diodes equals computer. What a project that was!

That guy buys a TA7642 and puts a few components on a board with it and thinks, "Oh what a brilliant fellow am I!". He even calls it a one active device radio. I guess he doesn't know the TA7642 has 10 transistors in it?

Anyway the point contact was the first transistor to achieve military standards and it was used in early computers. The cost and lack of supply channels was probably what killed them. The early components were soldered together so excess heat in installing them could kill one. This applied equally to the junction transistors. That was why they came with such long leads. The maker warned to place a heat sink on the lead between the solder joint and the tranny.

25 Cent Tunnel Diode?

I made some more point contact transistors and have been working on the forming process. The best yet is 5 shots with a 680ufd cap charged to 10 volts. As the junction forms the process is quicker so if 5 shots doesn't quiet do it try 1 more and test. It will go from close to to far in a single shot so reducing the charge is good when it is close. The old Point Contact were very reliable and stable once developed. Some people say it is the opposite! They were produced by hand one at a time and the variables had to be accounted for. The junction transistor was more easily produced, that's all. Cheaply made mass produced product win more often than not.

Anyway I wanted to post a simple tunnel diode fabrication. It looks like this.

If you can build the point contact diode and form it you can use an Aluminum cat whisker and form it more heavily than you would a transistor or detector diode and the result is a tunnel diode. So many things to try and so little time.

Another project in the making.

Anyway I wanted to post a simple tunnel diode fabrication. It looks like this.

If you can build the point contact diode and form it you can use an Aluminum cat whisker and form it more heavily than you would a transistor or detector diode and the result is a tunnel diode. So many things to try and so little time.

Another project in the making.

Monday, February 19, 2018

Point Contact Transistor build

My last post showed the close up view. Here you can see the block it is mounted in. It could be smaller but I'm using #12 wire and don't see the need to crowd things in the prototype.

I'm am feeding a signal into the transformer lower left and driving the telephone receiver center. It is not ear piercing but load enough I can hear it.

With all the leads attached it is not pretty but you can get a better view.

The scope tells the story. signal is passing through. Now the question is where to get the germanium? I have a couple of those 1N34As but , do I want to destroy one? Time to rumble through the junk bins.

I'm am feeding a signal into the transformer lower left and driving the telephone receiver center. It is not ear piercing but load enough I can hear it.

With all the leads attached it is not pretty but you can get a better view.

The scope tells the story. signal is passing through. Now the question is where to get the germanium? I have a couple of those 1N34As but , do I want to destroy one? Time to rumble through the junk bins.

Sunday, February 18, 2018

Making a point contact transistor

This is the first one. That germanium wafer was tiny. I did another with a wafer from a bigger diode.

It is now ready to be formed. I took a .5UF capacitor and charged it to 10v then discharged it through the junctions about 10 times and checked with the ohmmeter. When the junction formed the reading went down. I stopped forming the junction at about 1K Ohm. When I download the pictures from the camera I'll show the finished product.

Saturday, February 17, 2018

Germaniun Transistor Cross Reference

Transistor Cross Reference Germanium

This chart does have a couple of questionable entries. The same number being used by different manufacturers? The one I noted has two entries with the same number. One is NPN and the other is PNP. I have seen a FET and a junction transistor with the same number. It is a good reference just be aware the numbers may have been reused in the last 50 - 60 years since it was compiled. When you see a TO92 component listed as TO3 that's the indicator to be wary.

This chart does have a couple of questionable entries. The same number being used by different manufacturers? The one I noted has two entries with the same number. One is NPN and the other is PNP. I have seen a FET and a junction transistor with the same number. It is a good reference just be aware the numbers may have been reused in the last 50 - 60 years since it was compiled. When you see a TO92 component listed as TO3 that's the indicator to be wary.

Saturday, February 10, 2018

The Super Regen with a Mosfet?

A TRB member was looking at a vacuum tube Super Regen and asked can it be done with a FET? This is the circuit in question.

He offered this as an option.

The first step should be to look at how a Super Regen works.

The Regen is turned into a Super Regen by adding a switching circuit in the grid. So what does that do for us?

Ok the regen is oscillating and the quench breaks those oscillation up. The high frequency spurts are above our hearing range.

Input a modulated signal and the spurts are modulated at and audio rate. (follows the envelope.)

Now the original question. Can it be done with a FET?

I'm using a 2SK669 MOSFET. I bought a reel at 2 cents each so this is my go to MOSFET. I think a 2N7002 would be a close match. Anyway as you can see I used a transformer with three windings.

I adjusted the coils a little to see how it effected the circuit.

I think a pot across the feed back coil would be a good option.

You can see the coil on the gate is 1 millihenry. I wound a piece of wire about 24" long on a core (blue) and it was 1.8 millihenry. Putting a pot across the feedback coil would allow adjusting the circuit with a toroid core coil. So the original question, is it doable? The answer would be found by trying it.

This circuit would only require the input tank to be adjustable. The quench circuit could be fix tuned and the feedback could be adjusted with a pot.

EDIT:

The blue coil frequency response is up to 1Mhz.

He offered this as an option.

The first step should be to look at how a Super Regen works.

Ok the regen is oscillating and the quench breaks those oscillation up. The high frequency spurts are above our hearing range.

Input a modulated signal and the spurts are modulated at and audio rate. (follows the envelope.)

Now the original question. Can it be done with a FET?

I'm using a 2SK669 MOSFET. I bought a reel at 2 cents each so this is my go to MOSFET. I think a 2N7002 would be a close match. Anyway as you can see I used a transformer with three windings.

I adjusted the coils a little to see how it effected the circuit.

I think a pot across the feed back coil would be a good option.

You can see the coil on the gate is 1 millihenry. I wound a piece of wire about 24" long on a core (blue) and it was 1.8 millihenry. Putting a pot across the feedback coil would allow adjusting the circuit with a toroid core coil. So the original question, is it doable? The answer would be found by trying it.

This circuit would only require the input tank to be adjustable. The quench circuit could be fix tuned and the feedback could be adjusted with a pot.

EDIT:

The blue coil frequency response is up to 1Mhz.

Subscribe to:

Posts (Atom)